Are you looking for a beautiful, durable, naturally non-porous countertop that requires no maintenance? Look no further than Cameo Countertops, Inc. Our soapstone is elegant, cleans easily with soap and water, and can withstand chemicals, acids, or heat.

It is little wonder that soapstone countertops are growing in popularity among homeowners across the country. This completely natural surface has many distinctive benefits that you will not find in rivals like marble, quartz, or granite. Although soapstone offers amazing benefits, it also comes with cons that should be recognized before investing in a new countertop. To insure that you are pleased with your choice, we have put forth every effort to bring forward all of the pros and cons so to help you make a truly informed opinion about the new addition to your kitchen.

Mother Nature has put her best into producing this rock that is available in varying degrees of hardness. The softest type is used for sculpting, while harder stone is used for tables, kitchen work surfaces, wood burning stoves, tiles, etc. Durability is one of soapstone’s biggest bragging rights. It is common to see soapstone stoves and sinks that were manufactured in the 1800s still being used today in the northeast section of the United States. If you decide to incorporate soapstone into your kitchen, you can consider it a beautiful investment for life.

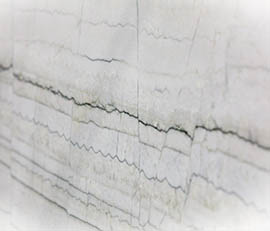

When it comes to any soapstone countertops, no two slabs are ever the same. The one that you have decorating your kitchen cannot be duplicated in another home. Your countertop will become a personal treasure, specifically unique to your home.

The color of the stone can vary depending on the area that it was derived from. The colors can range from an almost pale green, to a light gray. You will have the option of applying mineral oil to soapstone countertops to darken the look, or you can keep it looking natural and avoid the oiling process completely. Mineral oil does not have to be applied; therefore, you will have the choice between a lighter and a darker countertop based on your own personal preference.